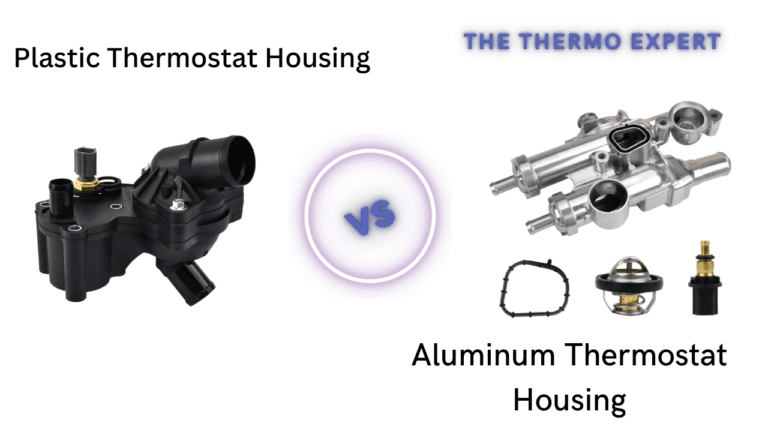

Plastic vs. Aluminum Thermostat Housing: Which One is Better for Your System?

The definitive guide to cooling system upgrades. We analyze thermal stress, longevity, and leak prevention to help you make the right choice.

If you have ever popped the hood of a modern vehicle—be it a BMW, a Jeep Wrangler, or a Ford Explorer—you may have noticed a disturbing trend: plastic engine components. Specifically, the thermostat housing. For decades, metal was the standard, but manufacturers shifted to composites to shave weight and reduce production costs.

However, as these vehicles age, owners are facing a common catastrophe: the dreaded coolant leak. The plastic housing warps, cracks, and fails, often leaving drivers stranded on the side of the highway. This has sparked a fierce debate in the automotive community: Plastic vs. Aluminum Thermostat Housing. Is the aftermarket metal upgrade the savior your engine needs, or is the OEM plastic engineered for a reason?

In this comprehensive comparison, we will strip down the marketing hype and look at the engineering reality. Before we dive in, it is crucial to understand the component itself. You can learn more about what a thermostat does in a car to appreciate why its housing is so critical to your engine’s survival.

Quick Comparison: Plastic vs. Aluminum

For those in a rush to fix a leak, here is the high-level breakdown of how these two materials stack up against each other.

| Feature | OEM Plastic (Composite) | Aftermarket Aluminum |

|---|---|---|

| Primary Advantage | Thermal insulation & lightweight | Extreme durability & crack resistance |

| Common Failure Mode | Cracking, warping at flanges | Corrosion (if poor coolant used) |

| Lifespan | 40,000 – 80,000 miles | Life of the vehicle (typically) |

| Cost | Low to Moderate | Moderate to High |

| Heat Transfer | Low (Insulator) | High (Conductor) |

| Seal Reliability | Degrades over time | Superior rigidity |

The Truth About Plastic (Composite) Housings

Why Do Manufacturers Use Plastic?

It is easy to blame “cost-cutting” for the prevalence of plastic parts, and while cost is a factor, it isn’t the only one. Modern thermostat housings are made from high-grade thermoplastics, usually glass-fiber reinforced Nylon 66 (PA66-GF30). This material is chosen for specific engineering reasons:

- Thermal Insulation: Plastic does not conduct heat well. This means the coolant stays hotter inside the housing and doesn’t soak up as much radiant heat from the engine block before entering the radiator.

- Smooth Internal Surfaces: Injection molding creates incredibly smooth internal passages, which reduces fluid turbulence and improves flow efficiency compared to rough sand-cast aluminum.

- Corrosion Resistance: Plastic will never rust. In cooling systems where owners might neglect coolant flushes, plastic is immune to the electrolysis that eats away at metal.

The Fatal Flaw: Thermal Cycling

Despite these benefits, plastic has an Achilles’ heel: thermal cycling. Every time you drive, the housing heats up to operating temperature (often 195°F to 220°F) and then cools down. Over years, this expansion and contraction make the plastic brittle. Eventually, the flange—where the housing bolts to the engine—warps. Once it warps, the gasket can no longer seal, leading to leaks.

If you suspect your housing is already failing, check our guide on how to tell if a car thermostat is bad to distinguish between a stuck valve and a leaking housing.

Standard OEM Replacement Housing

If you prefer sticking to factory specs, ensure you buy high-quality OEM replacements like ACDelco or Mahle.

Check Price on AmazonThe Upgrade: Why Switch to Aluminum?

Enter the aftermarket solution: Cast Aluminum or Billet Aluminum housings. These parts are designed to address the structural weaknesses of the factory plastic units.

Durability and Rigidity

The primary argument for aluminum is simple physics. Aluminum has a much higher tensile strength than plastic. It does not become brittle with heat exposure. An aluminum housing installed today will likely maintain its structural integrity for 15 or 20 years. Crucially, the mating surface (flange) is far less likely to warp, ensuring the gasket seal remains tight indefinitely.

The Heat Dissipation Factor

Aluminum acts as a heat sink. While plastic insulates, aluminum radiates heat. In high-performance applications or towing scenarios, this can be beneficial as it helps dissipate a tiny fraction of heat from the coolant. However, this also means the housing itself gets extremely hot to the touch, unlike plastic covers.

Potential Downsides

It isn’t all perfect. Aluminum housings are often sand-cast, which can leave rougher internal surfaces than molded plastic. Poor casting quality can lead to porosity (tiny leaks through the metal itself) in very cheap aftermarket parts. Furthermore, if you mix incompatible metals or use old coolant, you risk galvanic corrosion.

Choosing the right thermostat temperature is also vital when upgrading. If you are modifying your system, you might be considering a 160 vs 180 thermostat. Lower temps put less thermal stress on the engine, but aluminum can handle the heat of a 195 degree thermostat without breaking a sweat.

Top Rated Aluminum Upgrade Kit

This kit replaces the breakage-prone plastic housing with durable cast aluminum. Includes gaskets and bolts.

Check Price on AmazonHead-to-Head: Detailed Performance Analysis

1. Leak Resistance

Winner: Aluminum.

The number one reason for thermostat housing failure is a leak at the seam. Plastic housings warp imperceptibly over time, lifting the seal away from the engine block. Aluminum is rigid. Once torqued down to spec, it stays flat. As long as you use a high-quality gasket, an aluminum housing solves the chronic leaking issues seen in vehicles like the Jeep Wrangler JK or the Ford 4.0L SOHC engines.

2. Cost Effectiveness

Winner: Tie (Dependent on Timeframe).

In the short term, a plastic replacement is usually 20-30% cheaper than a quality aluminum upgrade. However, if you plan to keep the car for another 5 years, the plastic one will likely fail again. The aluminum housing is a “one-and-done” fix, making it cheaper in the long run when you factor in the cost of coolant and labor for a second repair.

3. Installation Ease

Winner: Plastic (OEM).

OEM plastic housings are manufactured to incredibly tight tolerances. They almost always fit perfectly. Aftermarket aluminum housings can sometimes have casting flaws where bolt holes don’t align perfectly, or the surface requires light sanding to ensure it is perfectly flat. While high-end aluminum parts fit well, cheaper ones can be a headache to install.

Pros & Cons Summary

Plastic Housing Pros

- OEM perfect fitment guaranteed.

- Does not corrode or rust.

- Smooth internal flow.

- Lower initial purchase price.

Plastic Housing Cons

- Becomes brittle and cracks over time.

- Warps at flanges causing leaks.

- Cannot withstand overtightening of bolts.

- Short lifespan (typically 5-7 years).

Aluminum Housing Pros

- Superior strength and durability.

- Resistant to warping and cracking.

- Can handle higher heat cycles.

- Permanent fix for chronic leak issues.

Aluminum Housing Cons

- Susceptible to corrosion if coolant is neglected.

- Potential for casting imperfections in cheap units.

- Slightly heavier (negligible for daily drivers).

- Higher upfront cost.

Signs You Need to Upgrade Immediately

Whether you currently have plastic or metal, knowing when the part is failing is crucial to saving your engine. Watch out for these symptoms:

- Coolant Puddles: A pool of green, orange, or pink fluid under the front center of your car.

- Sweet Smell: A maple syrup odor coming from the engine bay after driving.

- Overheating: If the housing cracks, air enters the system, causing airlocks and overheating. Read more on the signs of a bad thermostat.

- Visible Cracks: On plastic housings, you may see hairline white stress marks near the bolt holes or hose connections.

Frequently Asked Questions

Does an aluminum thermostat housing cool better than plastic?

Technically, aluminum dissipates heat better than plastic, but the effect on overall engine cooling is negligible. The thermostat housing’s job is to contain coolant, not cool it (that is the radiator’s job). The main benefit of aluminum is durability, not cooling performance.

Can I mix aluminum housing with a plastic intake manifold?

Yes, this is very common. Many upgrade kits for cars like the Ford Mustang or Jeep Wrangler bolt an aluminum housing directly to a plastic intake or engine block. Just ensure you use the correct O-ring or gasket to seal the different materials properly.

Why do BMWs use plastic cooling parts?

BMW and other European manufacturers prioritize weight savings and recyclability. The specific plastics they use are designed to last through the warranty period, but they are notorious for failing after 60,000-80,000 miles due to the high operating temperatures of modern engines.

Will an aluminum housing corrode?

Aluminum is resistant to rust but can suffer from galvanic corrosion or oxidation if the coolant becomes acidic. It is vital to change your coolant according to the manufacturer’s schedule to protect an aluminum housing.

Final Verdict: Which One Should You Buy?

The battle of Plastic vs. Aluminum Thermostat Housing has a clear winner for those seeking longevity.

Stick with Plastic if: You are on a strict budget, are planning to sell the car soon, or are restoring a vehicle to exact factory concours condition. Modern OEM plastic housings are adequate for general use, provided you accept they will need replacement again in 50,000 to 80,000 miles.

Upgrade to Aluminum if: You plan to keep the vehicle for the long haul, you live in a climate with extreme temperature swings, or you are tired of recurring leaks. For engines notorious for housing failures (like the Jeep 3.6L Pentastar or BMW N-series), the aluminum upgrade is widely considered an essential “bulletproofing” mod.

Don’t wait for steam to pour out from under your hood. Inspect your housing today, and if you see signs of seepage, make the switch.